First lotus fiber extracting machine invented

PSNews - It takes an artisan nearly two months to make a scarf from lotus silk. This is a hard job, especially when taking silk from thousands of lotus stems is very sophisticated. With the aim of improving the productivity while preserving the traditional craft, a group of students from universities in Hanoi have built an automatic lotus machine.

|

| Artisan Phan Thi Thuan and her lotus silk scarf. Source: VNP. |

In recent years, "Made in Vietnam" high quality lotus fiber silk products are exported to many countries in the world, generating benefits. However, the process of spinning lotus stems to silk thread, is all done manually.

Phan Thi Thuan, the first artisan in Vietnam who makes silk from the lotus plant, shared that: "It takes about ten days to spin about 3,000 lotus stems into extract 250g of lotus silk to weave a scarf. Lotus silk is as light and thin as smoke but it's quite costly as it needs much labor."

|

Realizing the potential of the lotus weaving craft, a group of students including Ngo Tran Minh Duc, Nguyen Van Thang, Tran Quoc Dat, Cao Anh Tu from the Hanoi University of Sciences and Technology and Luong Duc Trung from the Foreign Trade University started a project to build a lotus fiber extracting machine to raise the productivity of fiber spinning.

From mid-October 2019, the team started their project, designing and modeling machines. When they successfully made a model, they assigned each member of the project team to a job. Some were in charge of programming and designing electronic circuits, others were responsible for designing and assembling the machine.

|

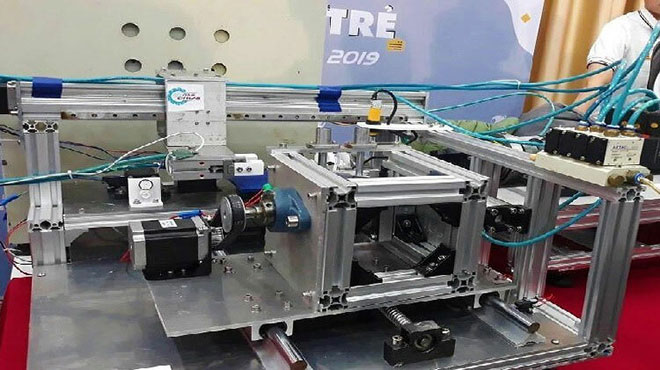

At first, the team faced many difficulties because such a machine had never been studied and developed before. With the energy and creativity of the youth, they have successfully created a machine after two months of research and development at a cost of only about 40 million VND.

The lotus fiber extracting machine includes three main sections. The first section is to take and hole lotus stalks, and cut them along. The second section is to take out lotus fiber from the stalk. The third section will spin fiber into thread. All working stages are operated automatically.

At the competition "Creative young Bach Khoa 2019" recently held in December 2019, the team won the first prize with their project.